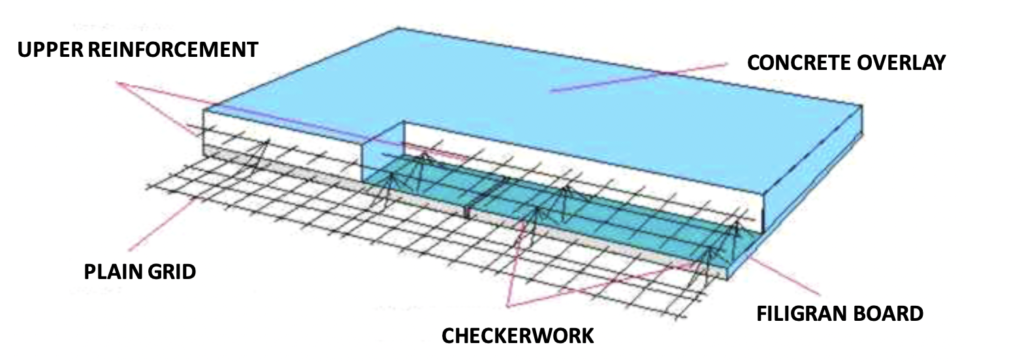

The beam and slab floor of a Filigran type is a universal system of reinforced slabs, used all over Europe. Due to its impeccable construction solution in a prefabricated building method that is adopted to industrial, living, rural and general construction it did not limit the inventions of the architects. The Filigran slab is a monolithic slab consisting of two main construction components i.e. from the prefabricated concrete slub of 5 cm thickness, called a structural boarding and the layer of the complementing concrete poured on the building site up to the level of foreseen in the construction project.

While it also uses the advantages of the monolithic and prefabricated. Structural prefabricated boarding “FILIGRAN” are the universal reinforced boarding with the additionally supporting scope checkerworks in a triangular shape. The checkerworks stick out over the upper layer of the boards and help while transporting and assembling.

Advantages of the beam and slab floor:

- Accuracy and smoothness of the beam and slab floor does not involve plastering

- Durability of the floors adopted to the individual pressure, in accordance with the conditions of the usage of the floor. Production of the floor at the construction site requires the minim level of boarding

- Possibility of using any shapes f.e. circle, triangle, polygons

- Possibility of using any types of the holes at the stage of prefabrication (for ventilation)

- Light boardings of 5cn – 125 kg/m2

- Simple and short period of assembling

- Possible assembling from the car without indirect storage

- Not much space is needed to store the boardings

- Universal application at any types of building construction

- Possibility of projecting the cross-reinforced slabs of any conditions of bearing

- Limitation of the time needed to assemble the slab

- Decrease of the amount of workers needed to prepare the slab

Main stretched reinforcement as well as diverted reinforcement along with the checkerwork are made of the steel A-IIIN.

Beam and slab floor “FILIGRAN” is made of concrete of B-25 class.

Complementary boards of “FILIGRAN” can be avoided by using expensive and time-consuming beam and slab floor of monolitical use. Its smooth bottom layer enables painting the ceiling without additional plastering.

Board is light itself (ca. 120 kg/m2) and can be assembled directly from the car at the building site. We also make it possible to produce the boards in accordance to investors’ technical documentation, taking into the account all of the dimensions, sizes of the boards, cuts for the technologic openings. The usage of the beam and slab floors “FILIGRAN” influences at good monolitization of the beam and slab floors that causes the bracing of the building as well as accelerates the cycle of investments in relation to traditional method of abour 40 – 50%. Technology of production of “FILIGRAN” guarantees the ideal smoothness of the bottom layers which eliminates plastering. The only elements that are being spackled are the joints of the floors.

Beam and slab floors “FILIGRAN”, produced in Baupol limited liability, are the newest technological solution used in modern building construction.

Technical parameters:

- Standard range – up to 9,5 m

- Width – maximum to 2,5 m

- Thickness of the board – 5 – 7 cm

- Thickness of the beam and slab floor – from 14 cm

- Payload – 1,5 – 10 kN

- Thickness of the layer over the concrete – 0,09 – 0,20 m for concrete prefabrication: class B30 or higher

- Fire integrity – 1 hour

- Reinforcement of each touch of the boards eliminates the effect of slab faulting

- Assembly without the usage of expensive and time-consuming boarding only with the usage of the assembly shoring